Professional R&D for the Needs of Industrial Compressed Air

Provide specialized compressed air solutions for different industries such as cement plants, glass plants, textile plants, cnc machine shop, etc.

Our R&D team provides true professional gas solutions by developing our products to meet various industrial characteristics and working conditions

- B&D Air Compressor Canton Fair live show

- Redefinition Intelligent Energy Saving |New Release of BD Sound of Heaven Series 2.0 Two-stage Compression

- B&D Air Compressor booth is 20.2 K 40-41, Area D Canton Fair

- Oil-free air compressorsand characteristics of largegas use scenarios

- AirCompressor B&D 2.0 Series Two stage Compression Intelligent

Personalized R&D for Different Industry Characteristics

Ceramic Industy

For applications which need big air capacity, but with dusty and bad working conditions

Textile Factory

Big air consumption, low-pressure 2~5bar.60% energy consumption of air compressors for of whole factory. High-quality compressed air is needed.Nearly 24h working of compressors.

Cement Plant

Big air consumption, air pressure 3~6 bar.The working environment of the compressor is dusty.

Glass Factory

Big air consumption, low pressure 2~4bar.The air compressor is the main power-consuming equipment in the factory. Highly reliable performance of compressor is needed as all compressors would work 24h a day and 7days a week.

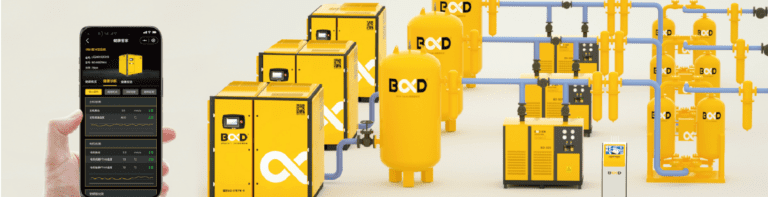

Innovative B&D,Intelligent Manufacturing

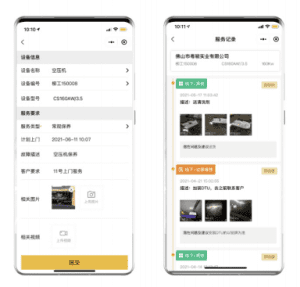

B&D cloud collects the operation date of the air compressor on-site in real time, and transfers data to thecloud server to provide users with various cloud data services.

1.Real time 2.monitoringHistorical data curve

3.Report statistics

4.Event information notification 5.Remote modification of parameters

visual maintenance services

In order to make the maintenance process of the air compressor more transparent and efficient. B8D cloud provides fully.

- One-click order for after-sale service

- Order status view

- Comments for after-sale service and maintenance

- File queries for service and maintenance

Knowledge library system of B8D Cloud provides information about the maintenance video course of air compressorthe introduction of air compressor principle,and the summary of the use of air compressor, so as to make users moreprofessional and more comfortable when using air compressor.

- Installation video

- Maintenance video.

- Principle introduction

- Problems summary

Main Products

Industrial Air Compressor Manufacturer

About B&D Group

As a well-known screw air compressor supplier in China, the main

business sector of Guangdong Baldor-tech Co., Ltd. (BD). Our Rotary

Screw Compressors are widely used in manufacturing industries like

textile, glass, cement, electronics (SMT), food process, hardware

fabrication, etc.

Blog

B&D Air Compressor Canton Fair live show

The Canton Fair, the full name of China Import and Export Fair, is one of the most important exhibitions in China’s economic opening and foreign trade. Since its inception in 1957, the Canton Fair has held one session, attracting business and purchasers from all over the world. The Canton Fair is held twice a year,

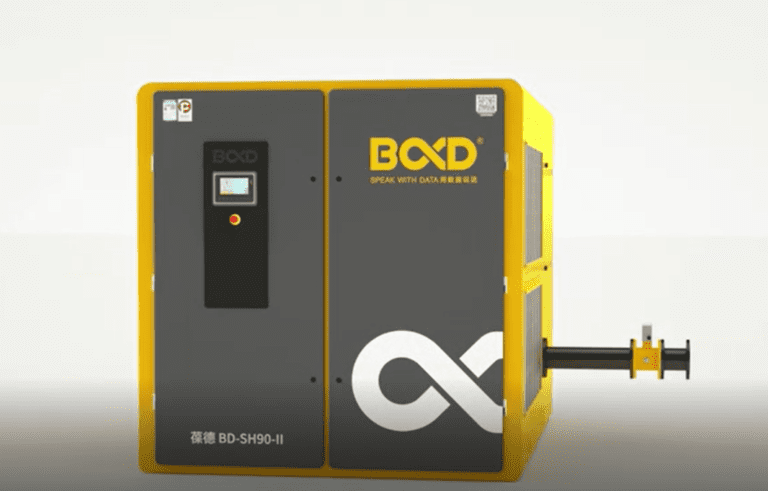

Redefinition Intelligent Energy Saving |New Release of BD Sound of Heaven Series 2.0 Two-stage Compression

Energy-saving air compressor that speaks with data Class 1 energy efficiency air compressor + digital energy efficiency platform Every spring and summer, BD releases new products. As a wind vane of technological innovation in the air compressor industry, each new product release by BD is an upgrade and redefinition. BD continues to launch innovative and

B&D Air Compressor booth is 20.2 K 40-41, Area D Canton Fair

Canton Fair time April 15-19, 2024 B&D Air Compressor-Guangdong Baldor-tech Co., Ltd.’s booth is 20.2 K 40-41, Area D Canton Fair Booth number: 20.2K 40-41 (Area D) welcome #aircompressor#chinafactory#bdcompressor email:[email protected] Whatsapp /tel +86 18200804101

Oil-free air compressorsand characteristics of largegas use scenarios

Oil-free air compressors do not require oil for lubrication, making them suitable for applications where oil contamination is a concern, such as in pharmaceutical, food and beverage processing, electronics manufacturing, and medical facilities. These compressors are designed to deliver clean, high-quality compressed air without the risk of oil carryover into the air stream. Characteristics of

AirCompressor B&D 2.0 Series Two stage Compression Intelligent

It seems like you are mentioning the “AirCompressor B&D 2.0 Series Two-stage Compression Intelligent” as a product or a specific model of an air compressor. If you have any questions or need more information about this product, feel free to ask. I’m here to help!

How to configure compressed air aftertreatment equipment for different industries

Configuring compressed air aftertreatment equipment for different industries involves designing a system that meets the specific quality requirements of the industry while ensuring efficiency and effectiveness. Here are some general steps to consider when configuring compressed air aftertreatment equipment for different industries: By following these steps and customizing the configuration based on the unique needs