EPM-II TWO-STACE

EPM-II Series

Two-stage compression is recognized as energy-savingmature in technology, stable and reliable.

- 1.Baldor EPM-l two-stage tandem compression air end can up to the newnational standard Class 1 energy efficiency.

2.Replacement for those air compressors with high energy consumptionor substandard performance.

3.Compared with single-stage compression, tandem two-stagecompression has at least 20% energy saving.

4.Eco-friendly silent, mature technology and reliable performance - 5.Equipped with energy efficiency monitor and health monitor to help yousave energy, reduce consumption and provide precise management.

- 6.New digital management system, inteligent sharing, human-machineintegration

Tandam Two-stage Compression Energy-saving Technology innovation

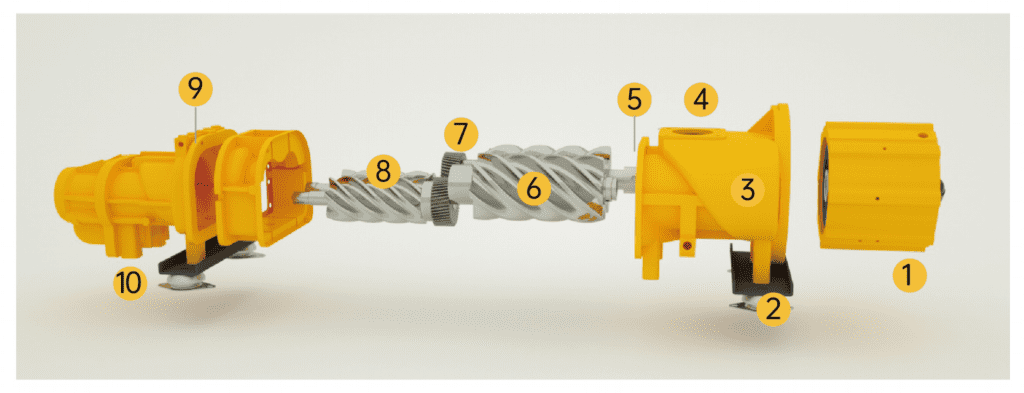

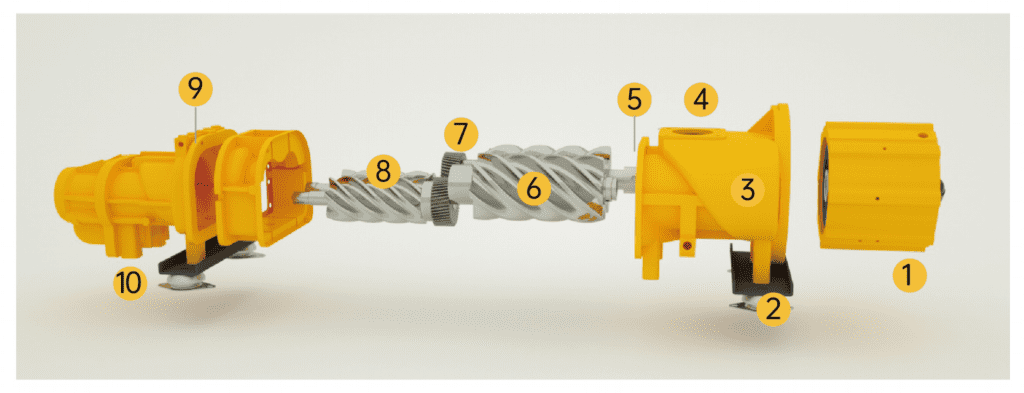

High-efficient, aluminum-alloy shell, IP65 oil-cooled PM motor,durable, reliable, energy-saving

Strong and stable, with minimal vibration.

High temperature resistance, excellent sound insulation and sealing

properties.

Scientific and reasonable diameter ensures air intake

The motor efficiency is transmitted to the rotor with good balance.

The steel rotor has high meshing degree, long life and more wearresistance.

High rotation efficiency and high matching density.

rotorsSteel rotors for secondary compression.

Air cooling, oil injection for shaft and secondary compression.

After being compressed, the oil-air mixture is discharged from thedischarge port.

Benefit predictions given by Health Monitor

| MODEL | Free Air Delivery / Discharge Pressure | Air discharge capacity (M³/min) | Power kW | Dimension L*W*H(mm) | Air outlet pipe diameter inch | Weight kg | Noise | Lubricant L |

| BD-22EPM-II | 0.7/0.6-0.8 | 1.68-4.2 | 22 | 1295*910*1250 | ZG1/4″ | 400 | 80±2 | 15 |

| BD-37EPM-II | 3.04-7.6 | 37 | 1498*1092*1480 | ZG11/2″ | 610 | 79±2 | 22 | |

| BD-55EPM-II | 5.08-12.7 | 55 | 1695*1342*1740 | ZG2″ | 960 | 85±2 | 37 | |

| BD-75EPM-II | 6.6-16.5 | 75 | 1898*1442*1895 | ZG2″ | 1200 | 85±2 | 57 | |

| BD-90EPM-II | 8.08-20.2 | 90 | 2198*1642*2015 | DN80 | 1450 | 88±2 | 100 | |

| BD-110EPM-I | 9.68-24.2 | 110 | 2198*1642*2015 | DN80 | 1500 | 88±2 | 100 | |

| BD-132FPM-I | 11.2-28.0 | 132 | 2198*1642*2015 | DN80 | 1600 | 88±2 | 100 |

| MODEL | Free Air Delivery / Discharge Pressure | Air discharge capacity (M³/min) | Power kW | Dimension L*W*H(mm) | Air outlet pipe diameter inch | Weight kg | Noise | Lubricant L |

| BD-22EPM-I | 1.0/0.8-1.0 | 1.52-3.8 | 22 | 1295*910*1250 | ZG1/4″ | 400 | 80±2 | 15 |

| BD-37EPM-II | 2.72-6.8 | 37 | 1498*1092*1480 | ZG11/2″ | 610 | 79±2 | 22 | |

| BD-55EPM-I | 4.56-11.4 | 55 | 1695*1342*1740 | ZG2″ | 960 | 85±2 | 37 | |

| BD-75EPM-I | 5.68-14.2 | 75 | 1898*1442*1895 | ZG2″ | 1200 | 85±2 | 57 | |

| BD-90EPM-II | 7.16-17.9 | 90 | 2198*1642*2015 | DN80 | 1450 | 88±2 | 100 | |

| BD-110EPM-II | 8.32-20.8 | 110 | 2198*1642*2015 | DN80 | 1500 | 88±2 | 100 | |

| BD-132EPM-II | 9.44-23.6 | 132 | 2198*1642*2015 | DN80 | 1600 | 88±2 | 100 |