Recently, seven departments including the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Finance, the People’s Bank of China, the State Administration of Taxation, the State Administration for Market Regulation, and the State Administration of Financial Supervision jointly issued the “Implementation Plan for Promoting Equipment Updating in the Industrial Sector”. This notice further improves the implementation policy of fully covering the digital transformation of industrial enterprises in major industrial provinces, major cities and key parks, ensuring that production capacity below the energy efficiency benchmark level in key industries is basically phased out, and that the energy efficiency of major energy-consuming equipment basically reaches the energy-saving level.

Accelerating product upgrading is an important measure to promote high-quality development. The state is encouraging and guiding a new round of large-scale equipment updates and the trade-in of consumer goods. B&D actively responds to the national replacement policy, allowing users to use new energy-saving smart air compressors as soon as possible, using data to drive energy saving and consumption reduction, and improve productivity.

The three major elements needed for manufacturing production are electricity, gas and water. Among them, the "gas" part of the electricity consumption of the air compressor station is as high as 40% to 70% of the entire factory's production electricity consumption.

Traditional air compressor stations have problems such as lack of management and energy consumption supervision, frequent loading and unloading, excessive pressure drop and pressure loss, pipeline leakage, lack of predictive maintenance, and lack of production supervision at the gas end. These various wasteful behaviors lead to high energy costs for air compressors. Air compressor stations rely on manual management, and data is difficult to record in a timely and reliable manne

Based on the user’s industry, B&D customizes one-stop industrial digital energy-saving solutions for users, from air compressors, post-processing equipment, pipelines, air compressor station system joint control, to whole plant water, electricity and other energy management. In this way, costs can be reduced and efficiency increased, and the development of new productive forces can be facilitated.

01 Class 1 energy efficiency replacement of high-energy-consuming air compressors

High-energy-consuming air compressors have high noise, high energy consumption, high maintenance costs, and face the risk of unscheduled shutdowns, affecting enterprise production.

B&D first-class energy-efficient air compressors are famous for their energy saving, stability and reliability. The products have been selected into the national energy-saving product recommended catalog for many times and won many energy-saving and quality awards.

After replacing the high-energy-consuming air compressor, it is expected to save more than 30% of energy for the enterprise. For example, replace the fixed speed drving 37KW and below with single-stage permanent magnet variable speed driving, and replace a single-stage fixed speed driving machine or variable speed drving machine from 55KW to 200KW with two-stage compression.

02 Digital Transformation

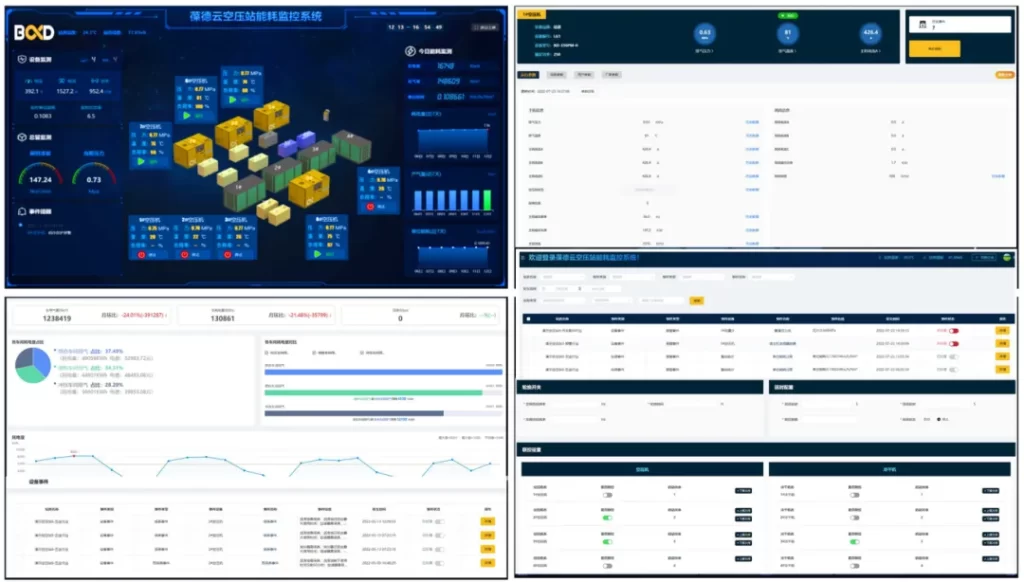

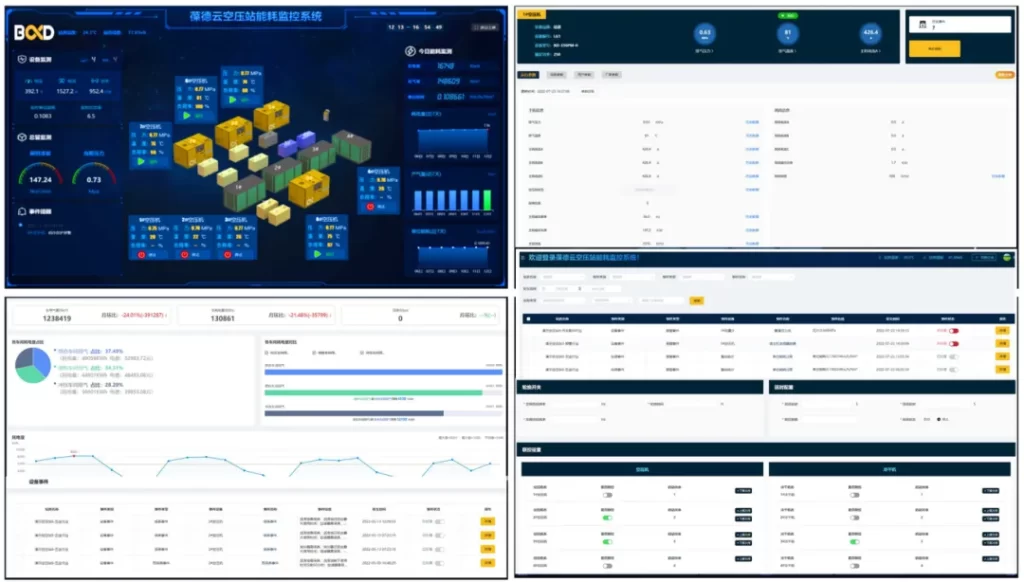

Through the smart air station of the Internet of Things and AI, on-site data collection is carried out on the air compressor station, and key operational data such as the gas-to-electricity ratio and power consumption of the air compressor station and each unit can be accurately calculated and analyzed. Real-time energy consumption monitoring, automatic meter reading, remote management, etc. can be used on the central control PC large screen and mobile phone terminals. On the basis of energy saving and consumption reduction, the accuracy of data and the real-time nature of reports are greatly improved.

B&D Intelligent Air Compressor Station intelligently controls each equipment in the air compressor station based on actual production needs. Intelligent on-demand switching reduces power consumption and extends the life of the air compressor. B&D intelligent air compressor station helps enterprises reduce consumption, increase efficiency and achieve lean management, with an estimated energy saving of 7% to 15%.

03 Energy Regulation

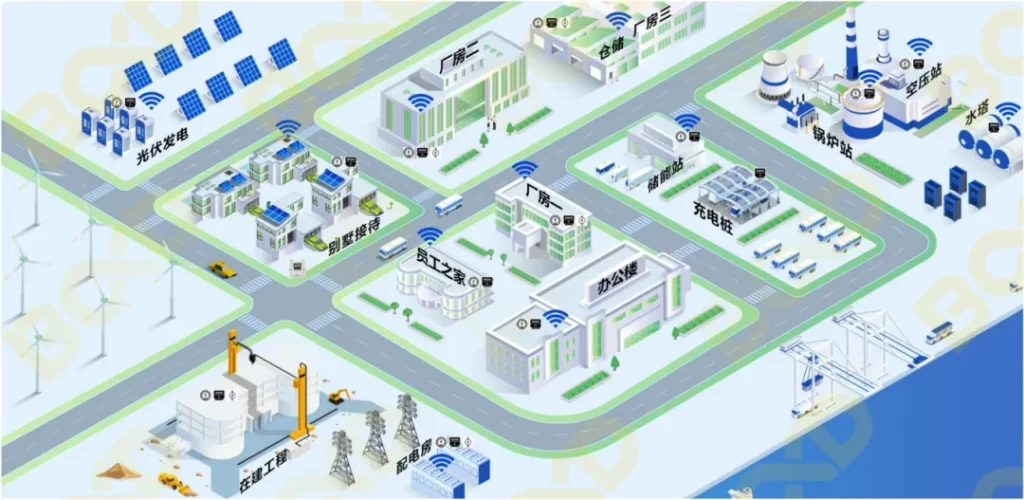

Relying on B&D Industrial Internet of Things and using big data, cloud computing, AI and other technologies, it provides a smart comprehensive energy management platform for electricity, water, gas, cooling, heat, light, storage, charging and other scenarios in user factories. It can provide centralized monitoring, process optimization and digital management solutions for energy supply, transportation and consumption.

Smart energy mainly collects, monitors, and analyzes various energy data including electricity, water, and gas. The effective use of energy consumption statistics provides a basis for management decisions.

The use of smart energy solutions reduces labor costs, improves energy management levels, and promotes users to realize the digital transformation of energy. Taking the application of B&D Industrial Park as an example, the B&D Energy Management Platform saves more than 1 million yuan in water, electricity and air energy every year.

B&D actively responds to the country’s large-scale equipment update plan, focusing on digital transformation and green upgrades, promoting high-end, intelligent, and green development of the manufacturing industry, and helping users save energy, reduce consumption, and digitally transform energy management.