In China, there is no shortage of new products in the air compressor market. What is lacking are truly good products that combine technological breakthroughs and innovation.

Especially in the field of oil-free air compressors, the creation of a good product is particularly important for the development of Chinese domestic brands.

As a cutting-edge manufacturer of intelligent permanent magnet variable frequency energy-saving air compressor technology in my country, B&D Technology bravely ventures into the “no man’s land” of technology, breaks international barriers through in-depth independent scientific research, and independently develops oil-free series, including oil-free scroll air compressors. (3.7-7.5kW), oil-free water lubricated air compressor (7.5-55kW), oil-free screw blower (37-75kW), dry oil-free air compressor (55-315kW), oil-free centrifugal air compressor (160 -2000kW), magnetic levitation centrifugal air compressor (110-350kW) powerful product array.

Of course, as a smart marathon runner and a smart innovative brand, B&D will not be satisfied with just a short lead, but will insist on continuing to run and constantly surpass itself.

In particular, B&D dry oil-free air compressors, with their excellent performance, have been able to outlast a number of foreign-funded and domestic oil-free air compressors and play a trump card.

This is an innovative masterpiece that contains black technology, independent research and development, independent production, and is positioned on the oil-free track.

Features of B&D dry oil-free machine

high air quality

Level 0 oil-free standard and overall oil-free design avoid air pollution by oil mist. It is designed to provide high-quality clean, oil-free compressed air for food and beverage, medical and pharmaceutical, precision electronics and other industries.

low maintenance cost

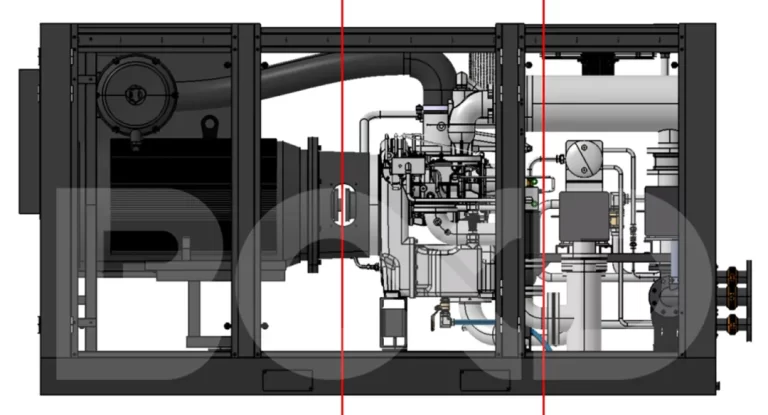

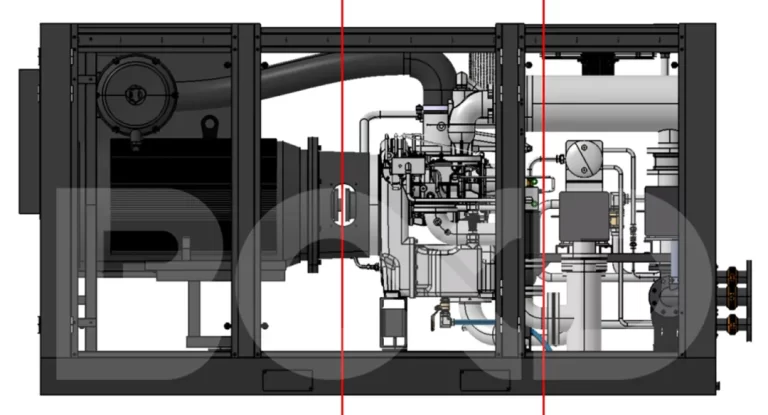

Modular design and reliable parts increase the life of components. Since there are no wearing parts such as lubricants, maintenance is easy. Moreover, the frequency of replacement of maintenance parts of dry oil-free air compressors is low, and the maintenance intervals are long, which reduces the company’s workload. Downtime and repair costs.

ISO certification

Passed ISO 8573-1 Class 0 oil-free certification by TUV to reduce the risk of product contamination.

Energy saving and more environmentally friendly

It adopts advanced silencer technology and sound insulation materials, runs smoothly, has low noise, and does not require lubricating oil. Its operating indicators comply with environmental standards.

Intelligent and humanized

B&D cloud intelligent management system, remote management, digital and humanized.

Longer life

Dry-type oil-free air compressors have a long service life, especially if the host system does not have accidents or serious wear and tear, the oil-free air compressor can have a long service life.

Module customization

B&D dry oil-free air compressors include power frequency and variable frequency, and are equipped with a wealth of optional modules, which can be customized according to the specific needs of the company to meet the production needs of users and improve production efficiency.

One-stop worry-free delivery

Whether you are adding an oil-free air compressor room or replacing an old air compressor, B&D’s oil-free team can help you with quantity selection from oil-free machine room site selection, pipeline layout, machine model configuration, post-processing equipment combination, etc. Tailor-made oil-free solutions and installed by a professional installation and after-sales team.

The following is a case of a well-known Chinese group applying B&D oil-free air compressor station:

Innovative B&D has never stopped exploring energy-saving technology, iterating on Chinese technological components with ingenuity, and using independent scientific research to promote domestic brands to the world.