Industry is the cornerstone of economic development, in 2023, China’s economy industrial economy as a whole showed a steady upward trend, the manufacturing industry is expected to gradually improve. Looking ahead to 2024, although the external environment is increasingly tightening, the manufacturing industry is also facing increased competition, transformation and upgrading, rising costs and other risks and challenges. But with the continuous optimization of industrial development ecology, China’s industrial economy, especially the manufacturing industry is expected to continue the steady growth trend.

And how to make the manufacturing industry this thick family of excellent and strong, high-level planning to promote the modernization of industrial construction, is to promote the key to high-quality development of the economy.

Production of three major elements of electricity, gas, water, of which the air pressure station “gas” part of the power consumption up to the whole plant production power consumption of 40% to 70%.

The choice of air compressor is very important, the purchase of the wrong, resulting in air compressor electricity and life full life cycle cost is high, such as air compressor machine downtime, then lead to production stoppage stoppage.

How to choose the right air compressor for your business? Stability of quality is very critical.

Stability refers to the ability of a product or service to maintain a consistent level of performance and quality under a variety of environments and conditions. Stability of quality of products or services is the basis for companies to achieve sustained competitive advantage, improve productivity and reduce costs for users.

Strong qualifications

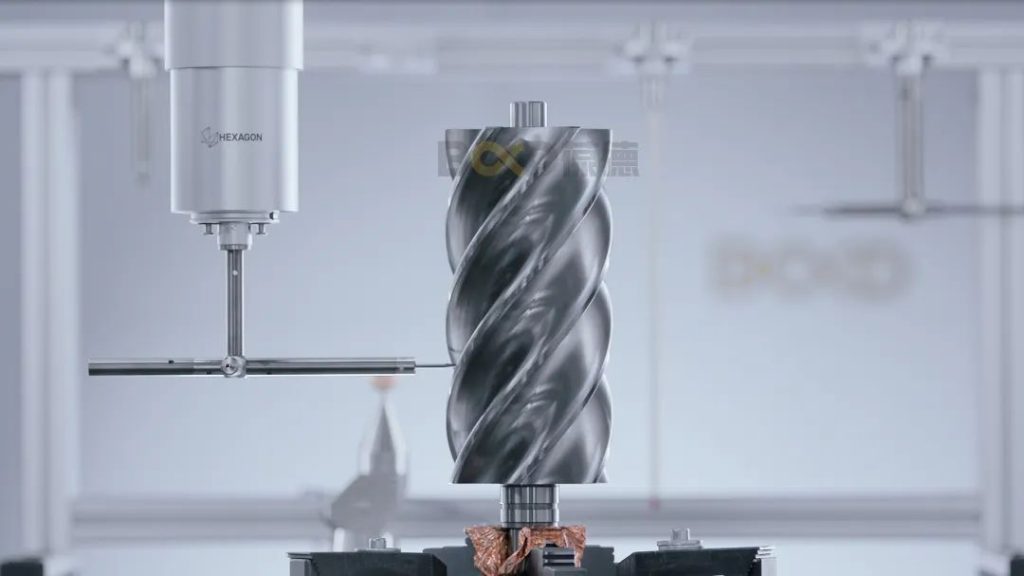

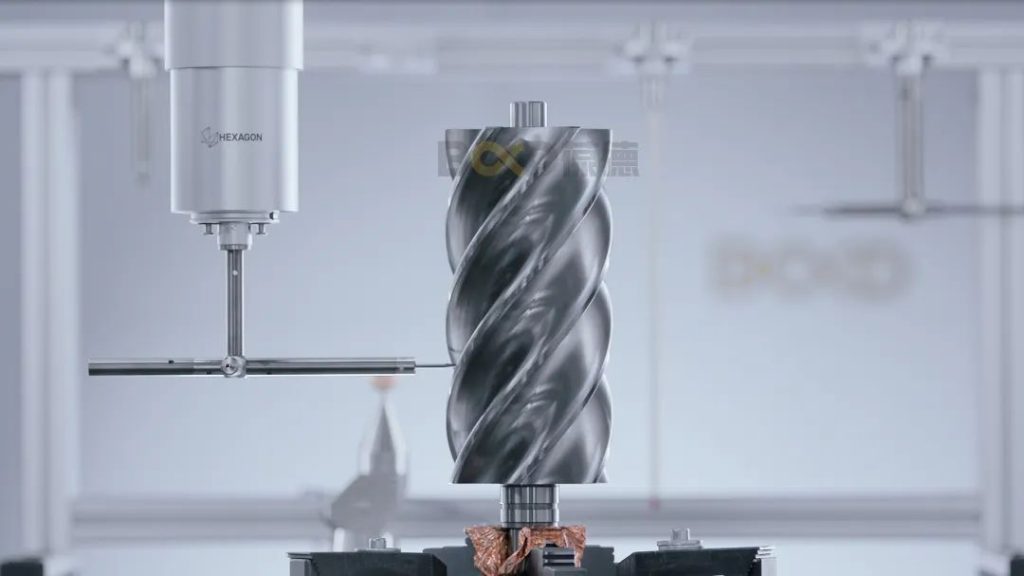

As one of the earliest manufacturers of R&D and production of intelligent permanent magnet frequency conversion air compressors in China, Pro-Tech has been plowing into the air compressor industry for more than 20 years, with rich experience in the industry. From the 3,000 square meters factory to the 100 acres of the air compressor industrial park, Pro-Tech owns a professional team, an 8-axis grinder mainframe R & D and machining center imported from Germany, professional three-coordinate testing equipment, and its own professional energy-efficiency laboratory, and its scaled-up production provides a strong guarantee of the quality of the products, and the quality of the products, no matter whether it is in terms of energy-saving performance, or the service life and reliability, the quality of the products is far better than that of assembled and processed factories.

Baldor

attaches importance to scientific research and innovation, won the National Specialized Specialized New Key Small Giant, Foshan City Digital Intelligent Demonstration Factory (2021 Foshan City, the first batch of three levels), the excellent level of intelligent manufacturing, so that the performance of Baldor air compressor products is more outstanding.

As a heavyweight technology manufacturer in the air compressor industry, Baldor participates in the drafting and formulation of a number of national and industry technical standards, which has witnessed the energy-saving and quality of Baldor products, among which Baldor’s energy-saving transformation ace products, the secondary compression series, have been selected as the energy-saving recommended catalogs for many years in a row, and the Baldor Tianqin series has been selected as the Energy Efficiency Star by the Ministry of Industry and Information Technology.

Reliable products

The answer to quality is right in front of your eyes when you enter Baldor’s open “transparent factory”. Because here, every detail of production is clear at a glance, from raw material storage, regulation, measurement, processing, assembly, monitoring, packaging and other processes, and the production data is also synchronized and displayed on the workshop’s data driving warehouse, so that every product can be traced throughout the whole process. Not only the transparency of data, but also the transparency of quality.

Precise data

Newly upgraded Baldor secondary compression 22-55kW, factory configured with smart meters, 75-450kW configured with smart meters plus vortex flowmeter, to achieve unified management of air compressor energy-efficiency data “energy-efficiency housekeeper”, through the collection of data, real-time monitoring of the energy consumption of the equipment and early warning, to assist the staff in timely discovery of energy consumption anomalies, and to provide data to support the improvement of energy saving for the smart.

Success Stories

Through continuous unremitting efforts, Baldor one-stop energy-saving solutions have realized the iterative upgrading from concept, mode to technical solutions, and assisted numerous cases of high-quality development in various industries with technology, services and solutions.

Up to now, Baldor has provided energy-saving, stable and reliable compressed air power services for 16W+ customers in different industry segments.